The 3DEXPERIENCE platform is known for its robust document management, BOM management and multi-CAD integration capabilities, and offers comprehensive tools for project, change and release management. With the migration to the cloud version, weba will be able to make its processes more location-independent and efficient by making project information accessible across locations in real time - a crucial component for global companies like weba.

Key features of the upgrade to 3DEXPERIENCE onCloud

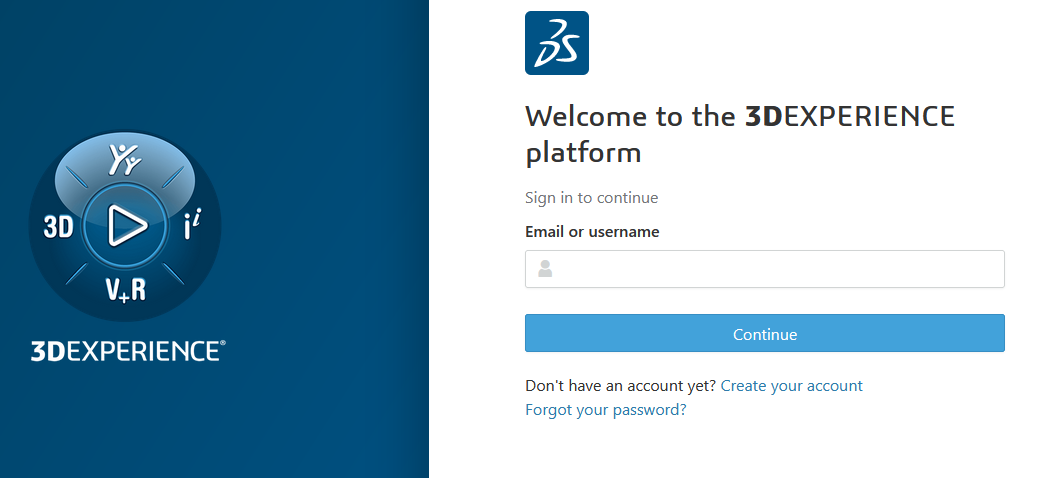

- Global accessibility and flexibility with a focus on security: employees can now access important data from anywhere and collaborate regardless of project or location, which also increases flexibility when working remotely and at customer appointments. Access is secured by multi-factor authentication (MFA), which creates an additional layer of security against unauthorized access. Further security measures such as data encryption and the use of virtual private networks (VPNs) guarantee the protection of sensitive information and ensure that only authorized persons have access to the data.

- Accelerated processes: The cloud platform enables faster responses to customer inquiries and efficient management of project changes and updates.

- Integrated error management: Faster communication channels and more effective error management directly on the platform.

- Innovative user interface: The modern user interface supports intuitive operation with functions such as drag & drop and personalized dashboards, which considerably simplify daily work. All information about the component is visible at a glance and links from documents and markups can be made directly to the component.

- 3D viewer in the browser: 3DExperience onCloud enables the display of components directly in the browser and offers users functions such as measuring, cutting, partial view and exploded view.

- Enterprise Integration Framework: The Enterprise Integration Framework enables the 3DExperience Cloud to be connected to on-premise systems. At weba, it is used for the automated creation of parts lists.

By using 3DEXPERIENCE onCloud, weba expects to save a considerable amount of time when searching for information and process customer projects more efficiently."The integration of this technology is an essential step in our digital transformation and reflects our efforts to always remain at the forefront of technological development and to continuously optimize our processes," explains Jörg Mitterhuber, Head of IT at weba Werkzeugbau.

To further optimize customer service and ensure transparent communication, we plan to introduce a dedicated customer portal.This portal will enable secure access to project-specific data.

About weba Werkzeugbau

Since its foundation in 1982, weba Werkzeugbau has established itself as a leading specialist in the field of toolmaking and forming technology.The company enjoys worldwide recognition, particularly in the specialized fields of hot forming and the production of tailored components. With over 300 qualified employees at three strategically important locations - the headquarters and development center in Dietach, Austria, the production facility in Olomouc, Czech Republic, and Gatzsch Schweißtechnik GmbH in Attendorn, Germany - weba combines state-of-the-art technology with comprehensive expertise. This synergy enables weba to develop and manufacture customized, innovative solutions that are precisely tailored to the demanding requirements of the automotive industry. Through continuous investment in research and development and close cooperation with OEMs and Tier 1 suppliers, weba sets new standards in quality and efficiency and strengthens its position as a preferred partner in a dynamic market.