For individualized and complex products, such as those found at weba Werkzeugbau, qualified employees are the most important success factors. Especially when rapid company growth on the international market leads to an increasing need for resources. But how and where can talented and qualified personnel be found? weba relies on the development of specialists in in-house training centers. This is where talented young people are trained in machining, toolmaking and, more recently, engineering.

Structured training plan for young talent in 3D design

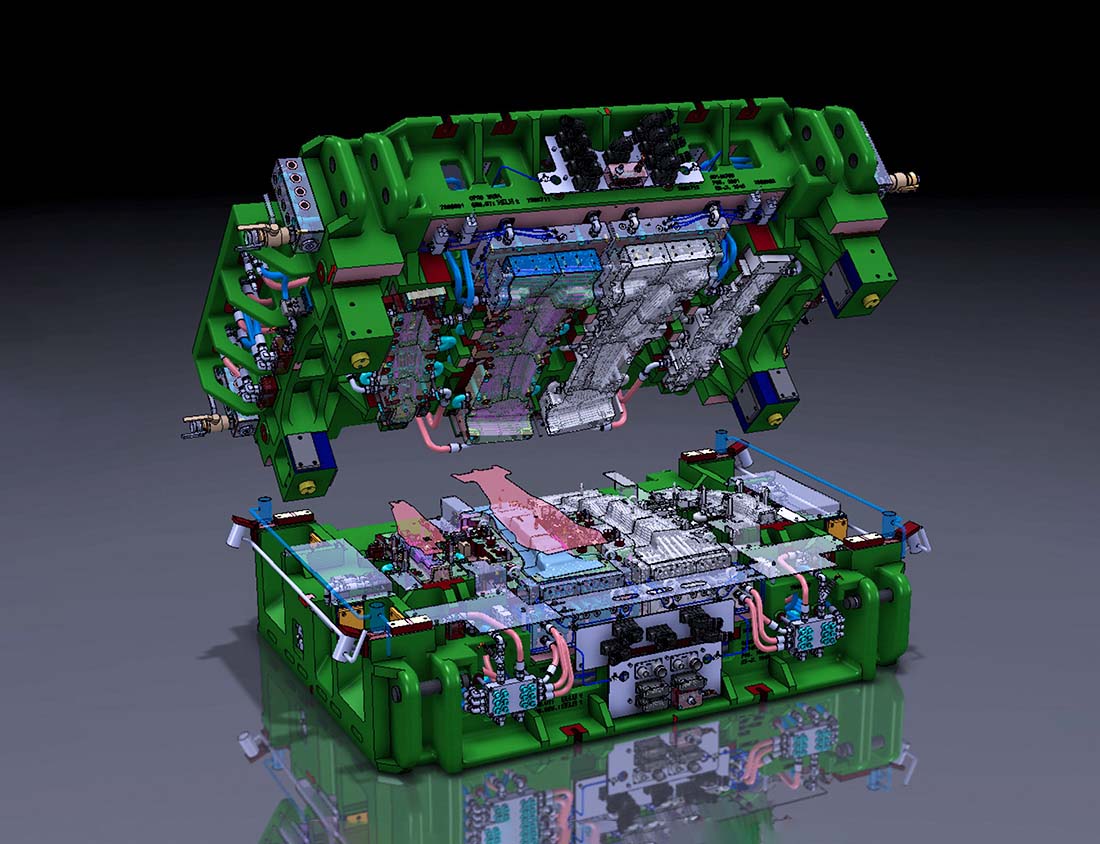

The program for young talent in 3D design was introduced in order to continue to meet the increased demand for design services. The training plan is structured in three phases. The first phase involves basic training with CATIA and other application programs such as ENOVIA or PMS. In the second phase, the young talents design practice tools independently, allowing them to familiarize themselves with weba's products and processes. This is followed by integration into the department and into everyday project work. In this phase, the trainees make changes to existing tool designs under the guidance of experienced colleagues.

The primary goal of the program is to employ qualified personnel in 3D design worldwide who cover the entire range of engineering services and also develop future-oriented, constructive tool solutions. In addition, design engineers from the global production locations are also trained and further educated here, ensuring uniform design standards and procedures in engineering across all locations.

Long-term strengthening of innovative power

With this comprehensive training program, weba not only secures its own need for highly qualified specialists, but also contributes to strengthening the company's innovative strength and competitiveness in the long term. Young talents are encouraged and supported in their development in order to master the technological challenges of tomorrow and continue to position weba as a leading provider in the field of high-level toolmaking and forming technology.

The future developers of innovative engineering ideas are thus already being trained at weba today in order to deliver pioneering solutions in the future and to meet the high demands of the automotive industry.

About weba Werkzeugbau

Since its foundation in 1982, weba Werkzeugbau has established itself as a leading specialist in the manufacture of tools for hot forming and cold forming technology. With over 300 qualified and dedicated employees at two different locations, weba combines state-of-the-art technology with in-depth expertise to provide its customers with customized and innovative solutions. The headquarters and development center in Dietach, Austria, is weba's creative hub where innovative ideas and advanced technologies are brought to life. The site in Olomouc, Czech Republic, focuses on the production of tools for hot forming.

weba is characterized by its innovative and quality-oriented corporate philosophy, which is focused on both the needs of the customers and the well-being of the staff. With steady growth and the expansion of its expertise, weba is committed to sustainable development and the promotion of young talent in order to remain a leading provider in the field of high-level toolmaking and forming technology in the future.