The decision to purchase the Hermle C 40 U machining center was made in order to significantly reduce set-up and programming times in milling. This is a decisive step towards meeting the constantly growing demands of the automotive industry and at the same time strengthening the competitiveness of weba Werkzeugbau.

Maximizing unmanned times through robot-assisted milling

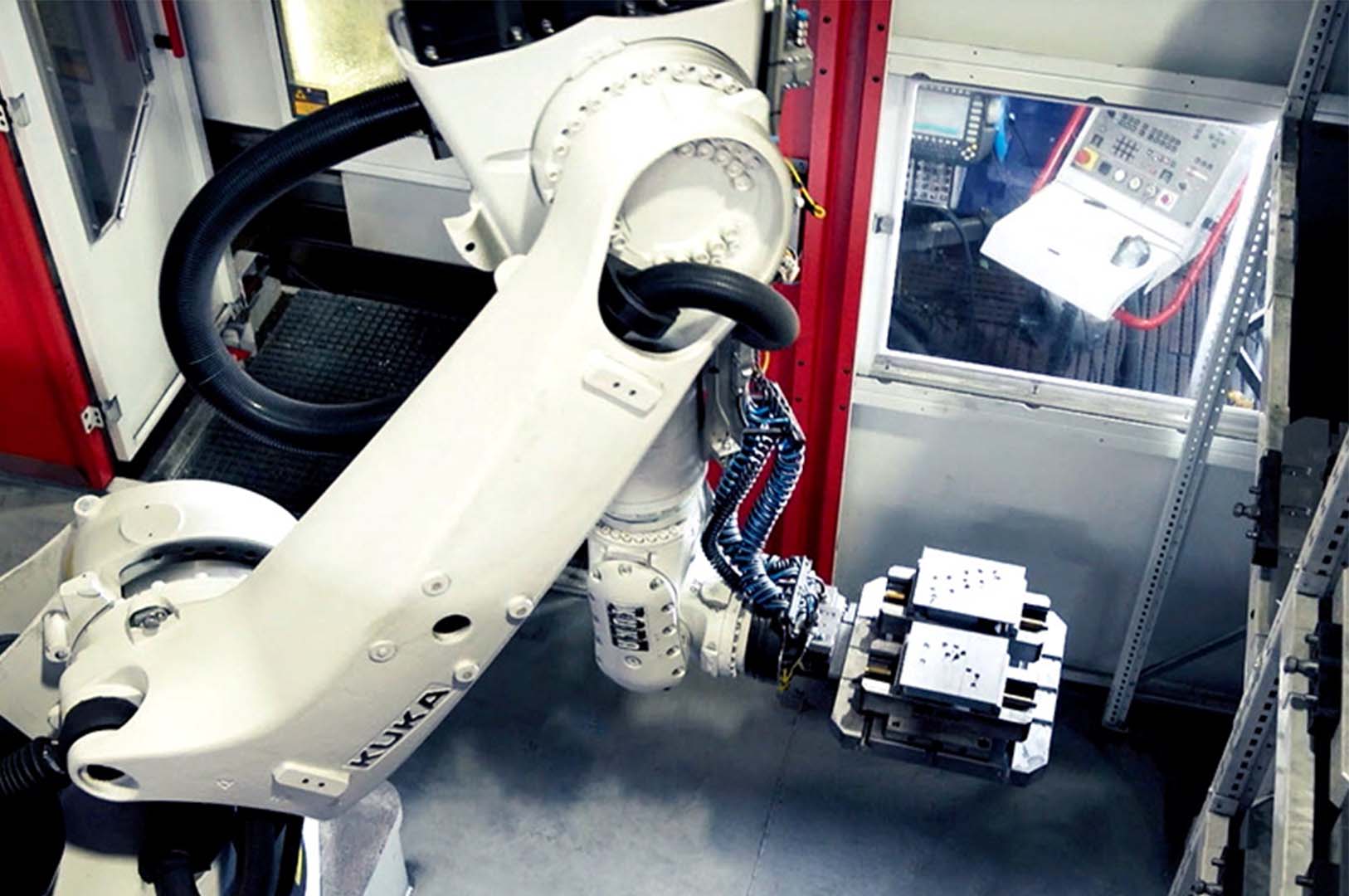

The universal machining center is equipped with a state-of-the-art robot cell. This technology not only enables outstanding precision and machining speed, but also significantly minimizes set-up times. Thanks to robot-assisted milling, weba can now guarantee highly flexible production around the clock. This expansion maximizes unmanned machining times and therefore makes a significant contribution to increasing efficiency.

“High-quality and economical milling of complex and demanding workpieces requires the use of powerful and dynamic machining centers,” explains Hannes Feuerhuber, Managing Director of weba Werkzeugbau. “With the Hermle C 40 U, we are expanding our machine park and setting new standards in production technology.”

The use of the new machining center enables weba to increase throughput enormously and at the same time greatly reduce the error rate. This not only means increased productivity, but also a significant improvement in the quality of the workpieces produced.

With this investment, weba Werkzeugbau is once again demonstrating that the company is prepared to invest in state-of-the-art technology in order to always be able to offer its customers the best solutions. The continuous expansion of the machine park at all locations underlines weba's claim to remain a leader in the industry and to further consolidate its reputation as a reliable partner for OEMs and Tier 1 suppliers in the automotive industry.

About weba Werkzeugbau

Since its foundation in 1982, weba Werkzeugbau has established itself as a leading specialist in the manufacture of tools for hot forming and forming technology. With over 300 qualified and dedicated employees at two locations, weba combines state-of-the-art technology with in-depth expertise to offer its customers customized and innovative solutions.